Durban is a mica insulated heater incorporating a Low Thermal Expansion Alloy outer sheath that is used as a uniquely designed Built-In Strap.

It is a proven heater design for good life efficiency and dependability. It assures maintaining the lowest winding temperatures possible, keeping a low-mass heating element assembly for fast heat-up and quick thermal response to controls. It incorporates the Low Thermal Expansion Built-In Strap, a unique design feature originally developed and patented by Tempco.

Construction Styles

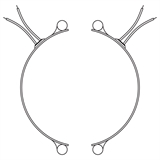

Two-Piece Band Construction

The Duraband two-piece construction provides a built-in hinge, making handling and installation easier. It is used on large cylinders or where the heater cannot be slipped over the end of the cylinder. Two-piece band heaters are rated at watts and volts per each half when ordering.

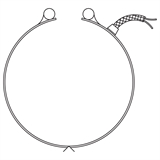

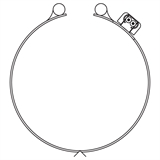

Type NS: Partial Coverage Band with Built-In Brackets (2 Piece)

Partial coverage band heaters are normally required when holes and cutouts will not allow the heater to sufficiently clear the machine obstructions. The preferred method of construction is the Two-Piece Band Heater with Built-In Brackets as illustrated. The heater is screwed down to the cylinder at the ends and the built-in Low Thermal Expansion Strap pulls the heater tightly against the cylinder being heated. The standard center of hole to the edge of heater dimension is 1/4″. When ordering, please provide the angle of coverage from center to center of the mounting screw holes as shown.

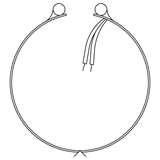

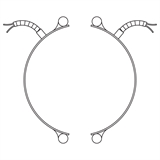

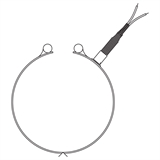

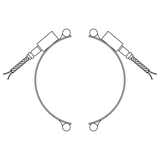

Type PS: Partial Coverage Band with Separate Strap (2 Piece)

The alternate method of partial coverage construction is the One-Piece Band Heater with a separate Two-Piece Strap. The two-piece strap itself is screwed down at the padded ends, allowing the heater to float between the pads as illustrated. When the strap is tightened, it will pull the heater against the cylinder being heated. The standard center of hole to edge of heater dimension is 1/4″. When ordering, please provide the angle of coverage from center to center of the mounting screw holes as shown.

Clamping Options

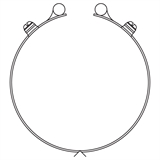

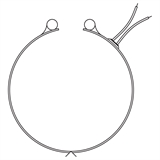

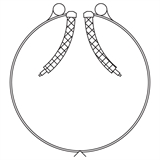

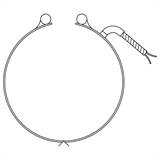

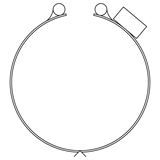

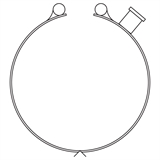

Type SB: Separate Straps, One-Piece Band

The Separate Strap clamping is available with any screw or lead termination and construction variation. It is strongly recommended that the Duraband with Built-In Strap design be used whenever possible because it provides more drawing power than any other type of clamping system.

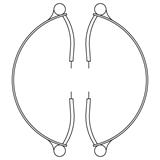

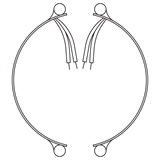

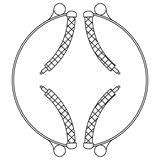

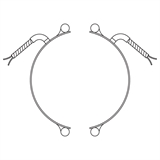

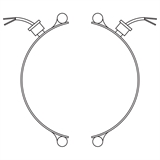

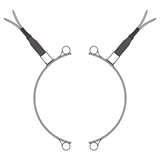

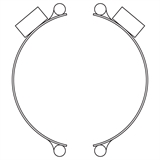

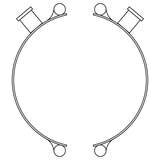

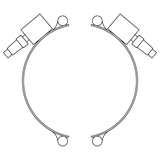

Type SS: Separate Straps, Two-Piece Band

The Separate Strap clamping is available with any screw or lead termination and construction variation. It is strongly recommended that the Duraband with Built-In Strap design be used whenever possible because it provides more drawing power than any other type of clamping system.

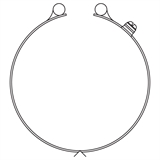

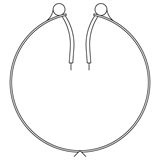

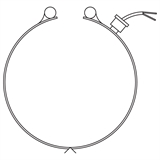

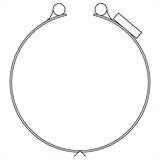

Type SE: Separate Straps, One-Piece Expandable Band

The Separate Strap clamping is available with any screw or lead termination and construction variation. It is strongly recommended that the Duraband with Built-In Strap design be used whenever possible because it provides more drawing power than any other type of clamping system.

Type SL: Spring Loaded with Built-In Bracket, One-Piece Band

The Heavy Duty Stainless Steel Spring with Built-In Bracket is a variation on the basic Duraband design. It is available with any screw or lead termination and construction variation. It is recommended for heaters over 12″ in diameter, and for any diameter heater used in the vertical position, to prevent the heater from slipping off the machine. The springs provide constant tension, therefore maintaining optimum surface contact against the cylinder being heated.

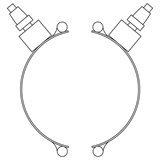

Type NSL: Spring Loaded with Built-In Bracket, Two-Piece Band

The Heavy Duty Stainless Steel Spring with Built-In Bracket is a variation on the basic Duraband design. It is available with any screw or lead termination and construction variation. It is recommended for heaters over 12″ in diameter, and for any diameter heater used in the vertical position, to prevent the heater from slipping off the machine. The springs provide constant tension, therefore maintaining optimum surface contact against the cylinder being heated.

Type NEL: Spring Loaded with Built-In Bracket, One-Piece Expandable Band

The Heavy Duty Stainless Steel Spring with Built-In Bracket is a variation on the basic Duraband design. It is available with any screw or lead termination and construction variation. It is recommended for heaters over 12″ in diameter, and for any diameter heater used in the vertical position, to prevent the heater from slipping off the machine. The springs provide constant tension, therefore maintaining optimum surface contact against the cylinder being heated.

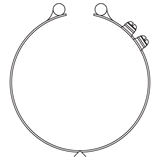

Type LT: Latch and Trunnion, One-Piece Band

The Latch and Trunnion Clamping System is available with any screw or lead termination and construction variation. It is ideal for absorbing thermal expansion due to the spring loading on the screws. The latch fully opens, facilitating installation on large-diameter cylinders. The outer sheath is made from a Low Thermal Expansion alloy.

Type LS: Latch and Trunnion, Two-Piece Band

The Latch and Trunnion Clamping System is available with any screw or lead termination and construction variation. It is ideal for absorbing thermal expansion due to the spring loading on the screws. The latch fully opens, facilitating installation on large-diameter cylinders. The outer sheath is made from a Low Thermal Expansion alloy.

Type LE: Latch and Trunnion, One-Piece Expandable Band

The Latch and Trunnion Clamping System is available with any screw or lead termination and construction variation. It is ideal for absorbing thermal expansion due to the spring loading on the screws. The latch fully opens, facilitating installation on large-diameter cylinders. The outer sheath is made from a Low Thermal Expansion alloy.

Type FE: Bent-Up Flange (Ears), One-Piece Expandable Band

The Bent-Up Flange clamping is available with any screw or lead termination and construction variation. The outer sheath is made from a Low Thermal Expansion alloy. The Bent-Up Flange design is best suited for narrowband heaters with small diameters.

Electrical Terminations

Type T1: Screw Terminals, One-Piece Band

Standard Termination Location: each side of the gap; center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 7/8″ (22.2 mm)

Post Terminals: 10-32 standard except 8-32 on < 1″ wide heaters & heaters with ID < 3″

Max. Volts/Amps: 480VAC/ 25A (10-32) or 20A (8-32)

Type T1: Screw Terminals, Two-Piece Band

Standard Termination Location: next to gaps on each half; center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 7/8″ (22.2 mm)

Post Terminals: 10-32 standard except 8-32 on < 1″ wide heaters & heaters with ID < 3″

Max. Volts/Amps: 480VAC/25A (10-32) or 20A (8-32) each half

Type T1: Screw Terminals, One-Piece Expandable Band

Standard Termination Location: each side of the gap; center of the width

Minimum Inside Diameter: 2-1/2″ (63.5 mm)

Minimum Width: 1-1/4″ (31.8 mm)

Post Terminals: 10-32 standard except 8-32 on heaters with ID < 3″

Max. Volts/Amps: 480VAC/ 25A (10-32) or 20A (8-32)

Type T2: Screw Terminals, One-Piece Band

Standard Termination Location: next to gap; center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 7/8″ (22.2 mm)

Post Terminals: 10-32 standard except 8-32 on < 1″ wide heaters & heaters with ID < 3″

Maximum Volts/Amps: 480VAC/ 25A (10-32) or 20A (8-32)

Type T2: Screw Terminals, Two-Piece Band

Standard Termination Location: next to the same gap on each half; center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 7/8″ (22.2 mm)

Post Terminals: 10-32 standard except 8-32 on < 1″ wide heaters & heaters with ID < 3″

Max. Volts/Amps: 480VAC/ 25A (10-32) or 20A (8-32) each half

Type T2: Screw Terminals, One-Piece Expandable Band

Standard Termination Location: next to gap; center of width

Minimum Inside Diameter: 2-1/2″ (63.5 mm)

Minimum Width: 1-1/4″ (31.8 mm)

Post Terminals: 10-32 standard except 8-32 on heaters with ID < 3″

Max. Volts/Amps: 480VAC/ 25A (10-32) or 20A (8-32)

Type T3: Screw Terminals, One-Piece Band

Standard Termination Location: next to gap; across the center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 2″ (50.8 mm)

Post Terminals: 10-32 standard except 8-32 on 2″ to 2-1/2″ wide heaters & heaters with ID < 3″

Maximum Volts/Amps: 480VAC/25A (10-32) or 20A (8-32)

Type T3: Screw Terminals, Two-Piece Band

Standard Termination Location: next to the same gap on each half; across the center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 2″ (50.8 mm)

Post Terminals: 10-32 standard except 8-32 on 2″ to 2-1/2″ wide heaters & heaters with ID < 3″

Maximum Volts/Amps: 480VAC/ 25A (10-32) or 20A (8-32) each half

Type T3: Screw Terminals, One-Piece Expandable Band

Standard Termination Location: next to gap; across the center of the width

Minimum Inside Diameter: 2-1/2″ (63.5 mm)

Minimum Width: 2″ (50.8 mm)

Post Terminals: 10-32 standard except 8-32 on 2″ to 2-1/2″ wide heaters & heaters with ID < 3″

Maximum Volts/Amps: 480VAC/ 25A (10-32) or 20A (8-32)

Type B1: Button Terminals, Two-Piece Band

Standard Termination Location: next to gaps on each half; center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 1-1/2″ (38.1 mm)

Screw Size: 10-32 standard except 6-32 on IDs < 5″

Maximum Volts/Amps: 480VAC/ 25A (10-32) or 20A (6-32) each half

Type B2: Button Terminals, Two-Piece Band

Standard Termination Location: next to the same gap on each half; center of the width

Minimum Inside Diameter: 2″ (50.8 mm

Minimum Width: 1-1/2″ (38.1 mm)

Screw Size: 10-32 standard except 6-32 on IDs < 5″

Maximum Volts/Amps: 480VAC/ 25A (10-32) or 20A (6-32) each half

Type B3: Button Terminals, Two-Piece Band

Standard Termination Location: next to the same gap on each half; across the center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 2-3/8″ (60.3 mm)

Screw Size: 10-32 standard except 6-32 on IDs < 5″

Maximum Volts/Amps: 480VAC/ 25A (10-32) or 20A (6-32) each half

Type C2: Standard Terminal Boxes, Two-Piece Band

Standard Termination Location: next to the same gap on each half; center of the width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 1″ (25.4 mm) Heater widths between 1″ and 2-1/2″ require a minimum ID of 5-1/2″ or greater.

Max. Volts/Amps: 480VAC/25A each half

Type C2: Standard Terminal Boxes, One-Piece Expandable Band

Standard Termination Location: next to gap; center of the width

Minimum Inside Diameter: 2-1/2″ (63.5 mm)

Minimum Width: 1″ (25.4 mm) Heater widths between 1″ and 2-1/2″ require a minimum ID of 5-1/2″ or greater.

Maximum Volts/Amps: 480VAC/25A

Type C5: Low-Profile Terminal Boxes, Two-Piece Band

Standard Termination Location: next to the same gap on each half; center of the width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 1″ (25.4 mm) Heater widths between 1″ and 2-1/2″ require a minimum ID of 5-1/2″ or greater.

Max. Volts/Amps: 480VAC/25A each half

Type C5: Low-Profile Terminal Boxes, One-Piece Expandable Band

Standard Termination Location: next to gap; center of the width

Minimum Inside Diameter: 2-1/2″ (63.5 mm)

Minimum Width: 1″ (25.4 mm) Heater widths between 1″ and 2-1/2″ require a minimum ID of 5-1/2″ or greater

Maximum Volts/Amps: 480VAC/25A

Type P1: High-Temperature Quick Disconnect Plugs, One-Piece Band

Standard Termination Location: next to gap; center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 1-1/2″ (38.1 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 572°F (300°C)

Type P1: High-Temperature Quick Disconnect Plugs, Two-Piece Band

Standard Termination Location: next same gap on each half; center of the width

Minimum Inside Diameter: 2″ (50.8 mm)

Minimum Width: 1-1/2″ (38.1 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 572°F (300°C)

Type P1: High-Temperature Quick Disconnect Plugs, One-Piece Expandable Band

Standard Termination Location: next to gap; center of the width.

Minimum Inside Diameter: 2-1/2″ (63.5 mm)

Minimum Width: 1-1/2″ (38.1 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 572°F (300°C)

Type P2: High-Temperature Quick Disconnect Plugs, Low-Profile, One-Piece Band

Standard Termination Location: next to gap; center of the width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 572°F (300°C)

Type P2: High-Temperature Quick Disconnect Plugs, Low-Profile, Two-Piece Band

Standard Termination Location: next same gap on each half; center of width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 572°F (300°C)

Type P2: High-Temperature Quick Disconnect Plugs, Low-Profile, One-Piece Expandable Band

Standard Termination Location: next to gap on each half; center of width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 572°F (300°C)

Type P3: DIN 49458 A/B Quick Disconnect Plugs, Vertical, One-Piece Band

Standard Termination Location: next to gap; center of width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 392°F (200°C)

Type P3: DIN 49458 A/B Quick Disconnect Plugs, Vertical, Two-Piece Band

Standard Termination Location: next to the same gap on each half; center of width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 392°F (200°C)

Type P3: DIN 49458 A/B Quick Disconnect Plugs, Vertical, One-Piece Expandable Band

Standard Termination Location: next to the same gap on each half; center of width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 392°F (200°C)

Type P4: DIN 49458 A/B Quick Disconnect Plugs, Horizontal, One-Piece Band

Standard Termination Location: next to gap; center of width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 392°F (200°C)

Type P4: DIN 49458 A/B Quick Disconnect Plugs, Horizontal, Two-Piece Band

Standard Termination Location: next to the same gap on each half; center of width

Minimum Inside Diameter: 3″ (76.2 mm)

Minimum Width: 2-1/2″ (63.5 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 392°F (200°C)

Type P4: DIN 49458 A/B Quick Disconnect Plugs, Horizontal, One-Piece Expandable Band

Standard Termination Location: next to gap; center of width

Minimum Inside Diameter: 2-1/2″ (63.5 mm)

Minimum Width: 3″ (76.2 mm)

Plug Electrical Ratings: 2-Pole 3-Wire Grounding

Maximum Volts: 250 VAC

Maximum Amps: 16A

Maximum Temperature: 392°F (200°C)

Additional Options

Igloo® Ceramic Terminal Covers

Igloo® Ceramic Terminal Covers consist of two individual ceramic parts. Unlike conventional ceramic caps, Igloo fully insulates any standard #8 or #10 terminal lugs used for electrical hook-ups.

Limitations

Minimum Inside Diamter: 2″ (50.8 mm)

Minimum Width: 1-1/4″ (31.7 mm)

To assemble Igloo covers, the terminal should be at least 7/8″ apart.

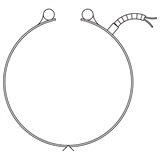

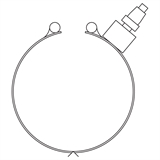

Thermocouple Bayonet Adapter

A standard Bayonet Adapter facilitates the installation of an external thermocouple with a standard bayonet cap. The standard location for the adapter is 90° from the gap. Specify without through-hole for heater sensing or with through-hole for load sensing. For heaters, less than 1″ wide order separate strap clamping and utilize the gap for the thermocouple.

Refer to Temperature Sensors for a complete selection of thermocouples available from stock.

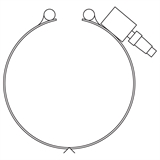

Thermocouple Coupling

The Thermocouple Coupling facilitates the installation of an external thermocouple with a threaded fitting to sense the temperature of the band. The standard location for the coupling is 90° from the gap. Specify without through-hole for heater sensing or with through-hole for load sensing.

Holes and Cutouts

Holes and cutouts are normally required in-band heaters for clearance for thermocouple probes or holding bolts. An oversize gap can in many cases serve the same purpose, saving the expense of the hole.

Using the center of the gap as a starting point, specify the location of the CenterPoint of the hole or cutout in terms of degrees and the distance from the edge of the heater. In addition, state the size of the hole or cutout.

For critical hole and cutout locations, a detailed drawing will be required.

Hinged Two-Piece Band

The Hinged Two-Piece Band Heater is connected with a continuous hinge for easy installation and removal. This heater can be opened and closed as often as is necessary. The preferred method of clamping is latch and trunnion. It is available with any screw or lead variation. When ordering, specify watts and volts each half.

Minimum Width: 1-3/8″ (34.9 mm)

Cone Shapes

Cone Shaped Heaters are normally used for special heating applications when heat is required for hoppers or funnels. They are made strictly to customer specifications. The preferred method of attachment is with built-in bracket clamping. When ordering or for quoting purposes, supply a detailed drawing or sample part. Include the top ID, bottom ID, and the vertical rise or heater width.

Special Custom Designs

No other heater band has the design and manufacturing flexibility of mica insulated heaters. Tempco’s flexible CNC sheet metal fabricating machines, custom-developed engineering programs with built-in intelligence, and experienced and talented engineering staff allow us to push the limits on band heater designs.

As a custom heating element manufacturer, we recognize that many applications require non-standard and unique designs. At Tempco, we are constantly challenged by our customers to solve their heating applications. When you have a special application and you want someone to work who has a “think outside the box” mentality, call Tempco.

Three-Phase

On very high wattage band heaters it would be advantageous to set up the wiring three-phase to reduce the current load across a single conductor. Three-Phase wiring is available on select clamping/construction or termination variation (termination location is subject to engineering approval).

Min. ID: 3″ (76.2 mm)

Min. Width: 2″ (50.8 mm)

Dual Voltage

Band heaters can be designed using 3-wire series/parallel circuits for dual voltage applications. Whether the heater is run on a higher or lower voltage, the wattage will be the same. Dual Voltage wiring is available on any clamping/construction or termination variation.

Ground Terminal or Lead

For those applications requiring a separate ground terminal or lead attached to the heater sheath. A Ground Terminal or Lead is available on any clamping/construction or termination variation.

Single Phase/Three Phase

Duraband Heaters can be designed with multiple circuits to operate single or three-phase.

Built-In Thermocouples

Heaters can be manufactured with a Built-In Thermocouple to closely control the temperature of the heater. Type J or K thermocouples are available with fiberglass, wire braid or any other required insulation.

All Stainless Steel Construction

All Stainless Steel Construction Mica band heaters can be constructed with an external sheath made entirely from stainless steel. This allows the Duraband to reach the maximum temperature of 1200°F (650°C). All Stainless Steel Construction is available on any clamping/construction or termination variation.

Other Sheath Materials

Other sheath materials, such as rust-resistant steel, Monel®, aluminum, or copper are also available for unique applications.

Terminal Lugs

Various types of crimp terminals can be attached to the heater leads to make wiring into applications quick and easy. High temperature 1200°F (649°C) ring terminals and nylon or PVC insulated terminals are available. Spade, ring, and right-angle or straight quick disconnect type terminals can be attached to the leads.

Sinuated Element

An alternative to wound ribbon core heaters is the sinuated heater element. In this type of construction, the heating element resistance wire is sinuated, or “formed” back and forth without a middle core layer of mica insulation. The heating element is then sandwiched between two layers of specially selected mica insulation to provide excellent thermal conductivity and dielectric strength. The sinuated formed element lends itself to lower temperature and watt density applications where high watt density construction is not required.

View all Tempco Band Heaters

Eagle Sensors, a division of Excel Automation, is an authorized Tempco Distributor. Contact us with any questions.