Tempco Mounting Methods

PSA (and PSA Plus)

For ease of attachment, specify PSA. Installation is simple: just peel off the protective liner and apply. It will adhere to most clean smooth surfaces. Care must be taken when installing to attain a smooth, consistent, uniform bond to achieve maximum results.

Maximum Temperature:

Continuous – 300°F (149°C)

Intermittent – 500°F (260°C)

Recommended Watt Density:

Under 5 W/in2 (0.78 W/cm2)

PSA Plus

A layer of aluminum foil is vulcanized to the back of the heater for added

heat dissipation prior to the application of PSA.

Factory Vulcanizing

Flexible heaters can be factory vulcanized to bare or anodized aluminum, Stainless Steel, Marble, or other hard surfaces for permanent attachment and excellent heat transfer.

The uncured silicone rubber heater is placed on the metal part and placed in the vacuum oven where the heater vulcanizes and adheres to the part in one operation. This procedure forms an extremely strong permanent bond with most metals due to the fact that the silicone rubber flows into and fills the micro structure in the surface of the metal. The metal part can be manufactured by Tempco or supplied by the customer. Consult Tempco for other materials including granite.

Magnetic Mounting

A flexible magnetic material can be attached to the back of a silicone rubber flexible heater. Will adhere to many varieties of steel. Ideal for those situations were you need to “Slap On” some heat! Specify when requesting a quote.

Maximum Temperature: 200°F / 93°C

Maximum Watt Density: 1 W/in2 (0.16 W/cm2)

Maximum Width: 24″ (610 mm)

Field Applied Adhesive

For a field applied permanent bond, a room temperature and ambient humidity curing silicone rubber adhesive is recommended. Tempco offers two types that will retain physical and electrical properties up to 500°F (260°C).

When using RTV adhesive, cover the heater completely with a thin layer of RTV, position the heater in place, and use a small roller to remove air bubbles, which could cause hot spots and lead to premature failure of the heater.

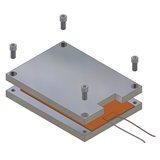

Clamping

Flexible heaters may be applied by clamping or compression between two rigid materials. The plate surfaces must be ground reasonably smooth. Care must be taken not to damage the heater or pierce the insulation. Mill out an area or cutout in the top plate for the added thickness of the lead exit area.

Recommended Maximum Pressure: 40 PSI

Outside Diameter Mounting

Mechanical fasteners are available for applicationsTempco has developed the techniques necessary to permanently mount silicone rubber heaters to the outside diameters of pipes and medium size vessels. This technique is particularly useful for heated drums and air or gas heating.

Minimum Diameter: 0.5″ (12.7 mm)

Maximum Diameter: 6″ (152.4 mm)

Maximum Length: 20″ (508.0 mm)

where flexible heaters must be detachable from cylindrical parts.