Tempco Flanged Immersion Heaters

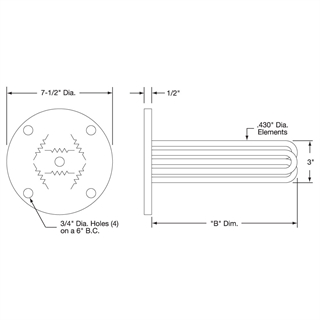

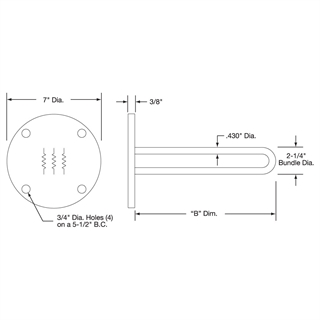

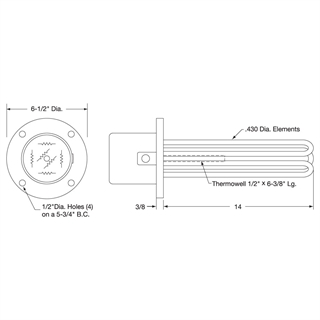

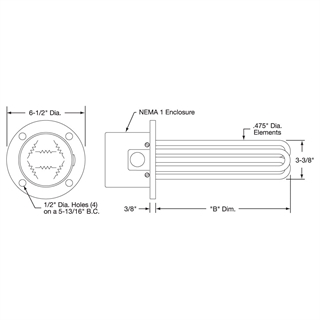

This design consists of tubular heating elements silver brazed or TIG welded to a flange cut from steel or stainless steel plate. Flange plate size, thickness and shape are determined by the application. A fiber gasket is supplied with each heater.

Eagle Sensors & Controls, Division of Excel Automation LLC, is an authorized Tempco distributor. Contact us for sales & technical support for Tempco heaters, Tempco sensors, Tempco temperature controllers, Tempco process heating systems & all other Tempco products.

Construction Styles

Request Custom Non-Pressure Rated Flanged Immersion Heater

If your filter selections do not return your desired results from our standard configurations, please continue to select your Specifications.

When you are finished, save your selections in the Wish List (using the button at the right of this page) and follow the steps to submit them to Tempco.

Sheath Materials

Incoloy 800

Nickel 30-35%, Chromium 19-23%, Iron balance.

The high nickel content of this alloy contributes to its resistance to scaling and corrosion. Used in air heating and immersion

heating of potable water and other liquids.

Copper

Standard Copper Alloy

A low temperature, inexpensive material used mainly for clean water heating.

Maximum Sheath Temperature: 350°F / 177°C

Steel

Low Carbon

Used for high to low viscosity oils, asphalt, tar, wax, molten salt, heat transfer liquid media and other compatible solutions.

Mounting Options

Electrical Terminations

Screw Terminals only

No Housing is needed for this heater.

Request Other Electrical Terminations

If your filter selections do not return your desired results from our standard configurations, please continue to select your Specifications.

When you are finished, save your selections in the Wish List (using the button at the right of this page) and follow the steps to submit them to Tempco.

Thermostats

Request Other Thermostat

If your filter selections do not return your desired results from our standard configurations, please continue to select your Specifications.

When you are finished, save your selections in the Wish List (using the button at the right of this page) and follow the steps to submit them to Tempco.

Thermostat Options

Stuffing Box Assembly

The Stuffing Box Assembly is used to seal the thermostat capillary when the sensing bulb (3/8″ max. OD) is immersed directly in a liquid rather than in a thermowell. The Stuffing Box consists of six slotted washers used to compress a graphite packing into a 3/8″ NPT male pipe thread fitting. Assembly Instructions Feed sensing bulb through hole in upper and lower fitting. Insert washers and packing into top cavity of lower fitting. Upper fitting then screws into lower fitting, creating the seal. Part Number: TST-109-101

Thermowells

Stainless Steel or Plain Steel: Thermowells provide protection for bulb and capillary sensors. They are supplied with a 1/2″ NPT male thread for mounting and a 3/8″ NPT internal thread that can be used with the stuffing box assembly to secure the capillary to the well. ID: 0.50″, OD: 0.56