Tempco Finned Tubular Heaters

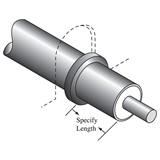

Finned heaters are constructed using Tempco’s robust tubular element as the basis of construction. Fin material is continuously spiral wound tightly onto the element surface to increase the convective surface area for air and non-corrosive gas heating. Fin spacing and size have been tested and selected to optimize performance. Steel finned units are then furnace brazed, bonding the fins to the sheath to increase conductive efficiency. This allows higher wattage levels to be achieved in the same flow area and produces lower sheath temperatures prolonging heater life. For higher temperature or more corrosive applications, stainless steel fins securely wound on alloy sheath are available. Application conditions such as vibration and toxic/flammable media should be taken into consideration when installing heaters. Protective coatings are available for use on steel finned heaters for mildly corrosive or high humidity applications.

Finned tubular elements are safer to operate than open coil heaters as the risk of fire from combustible particles in the flow stream and electrical shock is minimized. Increased service life and less maintenance required due to the rugged finned element construction. Power loading (w/in) of finned tubulars can be matched to any open coil installation.

Eagle Sensors & Controls, Division of Excel Automation LLC, is an authorized Tempco distributor. Contact us for sales & technical support for Tempco heaters, Tempco sensors, Tempco temperature controllers, Tempco process heating systems & all other Tempco products.

Finned Outside Diameter

.315″ dia. With 5/16″ fins

Outside Diameter: 92” OD

Fin Pitch Standards: 5±.5 for 5/16 material, 4.5-5 for 3/8 material (up to 6 per inch maximum

.315″ dia. With 3/8″ fins

Outside Diameter: 1.05” OD

Fin Pitch Standards: 5±.5 for 5/16 material, 4.5-5 for 3/8 material (up to 6 per inch maximum

.375″ dia. With 5/16″ fins

Outside Diameter: 98” OD

Fin Pitch Standards: 5±.5 for 5/16 material, 4.5-5 for 3/8 material (up to 6 per inch maximum

.375″ dia. With 3/8″ fins

Outside Diameter: 1.11” OD

Fin Pitch Standards: 5±.5 for 5/16 material, 4.5-5 for 3/8 material (up to 6 per inch maximum

.430″ dia. With 5/16″ fins

Outside Diameter: 1.04” OD

Fin Pitch Standards: 5±.5 for 5/16 material, 4.5-5 for 3/8 material (up to 6 per inch maximum

.430″ dia. With 3/8″ fins

Outside Diameter: steel fins—1.15”, SS fins 1.16”

Fin Pitch Standards: 5±.5 for 5/16 material, 4.5-5 for 3/8 material (up to 6 per inch maximum

.475″ dia. With 3/8″ fins

Outside Diameter: 1.21” OD

Fin Pitch Standards: 5±.5 for 5/16 material, 4.5-5 for 3/8 material (up to 6 per inch maximum

Sheath Materials

Incoloy 840

Nickel 18-20%, Chromium 18-22%, Iron balance.

Has about 10% less nickel than Incoloy 800. Used in many air heating applications, where it has exhibited superior oxidation resistance at less cost than Incoloy 800.

Incoloy 800

Nickel 30-35%, Chromium 19-23%, Iron balance.

The high nickel content of this alloy contributes to its resistance to scaling and corrosion. Used in air heating and immersion

heating of potable water and other liquids.

316/316L Stainless Steel

Chromium 16-18%, Nickel 11-14%, Iron balance.

(316L – Low Carbon)

Modified with the addition of Molybdenum (2-3%) to improve corrosion resistance in certain environments, especially those which would tend to cause pitting due to the presence of chlorides. Applications include deionized water.

Maximum Sheath Temperature: 1200°F / 649°C

304/304L Stainless Steel

Chromium 18-20%, Nickel 8-11%, Iron balance.

(304L – Low Carbon)

Used in the food industry, medical, and chemical heating.

Maximum Sheath Temperature: 1200°F (649°C)

Steel

Low Carbon

Used for high to low viscosity oils, asphalt, tar, wax, molten salt, heat transfer liquid media and other compatible solutions.

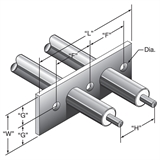

Mounting Options

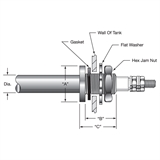

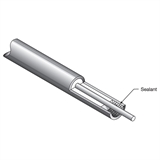

Type B – Bulkhead Fittings

Bulkhead fittings provide a leakproof method for mounting tubular heating elements through tank walls. Standard are round brass fittings crimped onto the element that are suitable for low pressure water (up to 80 psig) and non-pressure air. A brass hex nut, plated steel washer and gasket are supplied as standard.

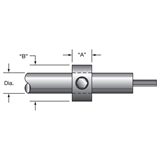

Type MC – Mounting Collar

Plated steel mounPlated steel mounting collars are locked in place with a set-screw and serve as an adjustable stop for through-the-wall mounting. Collars are shipped in bulk unless otherwise specified. Mounting collars can be ordered with the heater or purchased separately.ting collars are locked in place with a set-screw and serve as an adjustable stop for through-the-wall mounting.

Fin Materials

Steel Fins

Steel wound with copper wire between fins for oven brazing to sheath.

Fin Strip Width: 5/16” on .315, .375 and .430 diameters 3/8” on .315, .375 .430 and .475 diameters

Fin Thickness: 26 Ga. (.018); Optional 24 Ga. (.024)

Stainless Steel Fins

Stainless steel is mechanically wound but can be oven brazed as an option if a bright annealing atmosphere is used.

Fin Strip Width: 5/16” on .315, .375 and .430 diameters 3/8” on .315, .375 .430 and .475 diameters Fin Thickness (304SS): 26 Ga. (.018)

Surface Treatments

Oven Brazed & Annealed

This process produces a thin oxide coating on the fins & sheath. The copper braze material provides a further benefit by coating portions of the sheath. Suitable for most clean air applications containing low to moderate amounts of organic VOC’s and moisture.

High Heat Aluminum painted

High heat Aluminum paint available for steel finned units is suitable for use up to 700⁰F. It has good moisture resistance and provides the heater with a rust protective coating for ambient air applications containing organic or non-corrosive VOC’s. Recommended for use in most air duct applications.

High heat flat black painted surface

This is a high temperature, high emissivity, flat black coating which protects steel finned heater surfaces from oxidation while acting as a blackbody emitter. Usable up to 1000⁰F, it provides a radiant surface for free convection & low velocity convective applications.

Nickel plated steel finish

Nickel plated finish is available to provide the highest possible corrosion protection on steel finned heaters. Usable up to 500⁰F for salt water marine applications, air containing high concentrations of organic VOC’s, flue gas residues, ammonia, and many other chemical vapors. Please contact Tempco with your specific application requirements.

Bright Annealing

Bright annealed steel or stainless steel finned heaters produce a smooth bright finish. For applications requiring a clean un-oxidized surface with no rust or other contamination. Stainless finned heaters can be used in applications at higher temperatures and where moderate to high concentrations of organic or non-corrosive vapors are present.

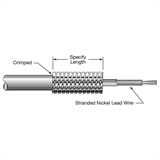

Electrical Terminations

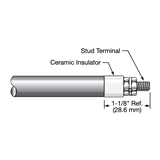

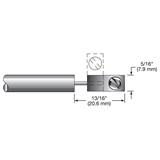

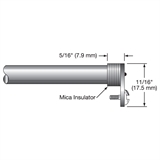

Type SF – Quick Connect Straight

1/4″ male (3/16″ optional) quick connect (slip-on) terminals are welded to the element terminal pin straight.

They provide quick and easy installation of lead wire with excellent holding force. Specify if an optional mica or ceramic insulator is required. Material: Nickel-Plated Steel.

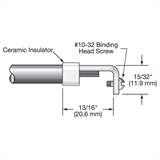

Type SF9 – Quick Connect 90°

1/4″ male (3/16″ optional) quick connect (slip-on) terminals are welded to the element terminal pin at 90° to the sheath.

They provide quick and easy installation of lead wire with excellent holding force. Specify if an optional mica or ceramic insulator is required. Material: Nickel-Plated Steel.