Tempco Cast-In Thermo-Platens

Tempco’s thermo-platens are made from aluminum, bronze and brass alloys. These materials provide excellent thermal conductivity for rapid heat transfer with uniform temperature gradients. To further enhance heat profiles, the formation and the location of the tubular heaters within the casting are precisely engineered using the latest computer design techniques. When the process requires heating and cooling cycles, thermo-platens can be manufactured with the addition of stainless steel tubing to provide liquid cooling capabilities. The working surfaces and/or contours of the thermo-platen can be machined to your specifications up to and including blanchard ground for extremely flat surface requirements.

Eagle Sensors & Controls, Division of Excel Automation LLC, is an authorized Tempco distributor. Contact us for sales & technical support for Tempco heaters, Tempco sensors, Tempco temperature controllers, Tempco process heating systems & all other Tempco products.

Cast Materials

Heating Element Exit Locations

Customer Specified

Customer specified: Please include detailed drawing when submitting to Tempco.

None

This cast-in will not have a heating element.

Electrical Terminations

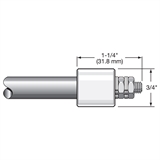

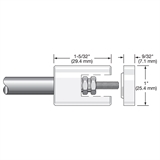

Type R1: Flexible Armor Cable

Flexible Armor Cable provides excellent protection to lead wires against abrasion and contaminants.

Available for .260″, .315″ and .430″ diameter heaters. Specify cable length and lead length. Style may vary from depiction depending on heater diameter and cable diameter used.

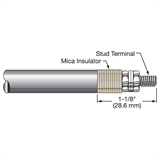

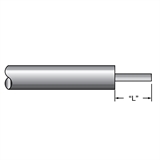

Type R1A: Stainless Steel Wire Overbraid

Stainless Steel Wire Overbraid provides flexibility and excellent protection to lead wires against abrasion.

Available for .260″, .315″ and .430″ diameter heaters. Specify stainless steel wire overbraid length and lead length.

Style may vary from depiction depending on heater diameter and braid diameter used.

Termination Protection

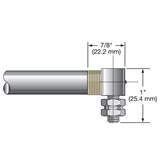

Type C2: Standard Terminal Box (on flat pad)

Type C2 is an individual terminal box for protecting the terminals on each Cast-In Band Heater half and on many other Cast-In Heater designs with one set of heater terminals.

The C2 box design requires a flat pad on half-round castings or a flat surface on other casting designs for mounting. It is made from heavy gauge, rust-resistant sheet metal. The cover is removable for easy access to terminals. The box has two 7/8″ diameter knockouts opposite each other for standard 1/2″ BX connectors.

Type P2: Quick Disconnect Plug Assembly with Box

Quick-Disconnect Cup assemblies provide the simplest and safest means for applying power to any type of Cast-In Heater installation. The box extends over the screw terminals on both Cast-In Band Heater halves. The combination of prewired cup and box assembly, along with factory prewired high temperature lead wire protected with armor cable, eliminates live exposed heater terminals and electrical wiring, protecting employees from electrical shock and the possibility of electrical shorts due to exposed wiring.

Type EP: Explosion & Moisture Resistant Box

Cast iron explosion and moisture resistant boxes should be used in areas where the surrounding air may become contaminated with combustible gases or a high humidity level may exist. Installation requires one box per Cast-In Heater half and they are brazed to the tubular heater. The standard box has one 1/2″ NPT hub.

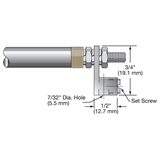

Type MPR: Moisture Resistant Box

This design has a moisture resistant die cast aluminum box with a non-removable polyurethane gasket in the lid. Lid is secured with captive stainless steel screws. Body and lid are painted in basic industrial gray; interior contains copper ground screw. Box is mounted to a plate that is brazed to the element. Available in a wide variety of sizes.

Type MR1: Moisture Resistant Box with Shield

This design incorporates the MPR housing style along with a perforated tube shielding unheated extensions of the tubular heating elements. This feature provides mechanical strength to the element extension and prevents overheating of the terminals, reducing possible premature failure from corrosion and oxidation.

None

This Cast-In will not have Terminal Protection.

Cooling Tube Exit Locations

Customer Specified

Customer specified: Please include detailed drawing when submitting to Tempco.

None

This cast-in will not have cooling tubes.

Cooling/Flow Tube Fittings

Type HS: Hi-Seal Fittings

Hi-seal brass fittings are highly dependable under the most adverse conditions. For reliable and trouble-free service with ease of installation, we strongly recommend hi-seal fittings.

Available for 3/8″ and 1/2″ diameter tubing. Male thread is 1/2″ NPT for 1/2″ tube and 3/8″ tube.

| Diameter Tubing |

Part Number |

|---|---|

| 3/8″ | FTG-118-124 |

| 1/2″ | FTG-118-116 |

Type RA: 90° Copper Elbow

90° copper elbow is brazed to the Cast-In Heater cooling tube extension with additional tube extension for connecting cooling lines with compression and/or flared fittings.

Available for 3/8″ and 1/2″ diameter tubing. If required, specify.

| Diameter Tubing |

Part Number |

|---|---|

| 3/8″ | FTG-127-102 |

| 1/2″ | FTG-127-103 |

Type RT: Cast Brass 90° Elbow

90° threaded elbow is brazed to the cooling tube extension,

providing an easy and quick method for connecting cooling lines. Recommended to be factory installed to assure good braze seals.

Available for 3/8″ and 1/2″ NPT internal threads. If required, specify.

| Diameter Tubing |

NPT | Part Number |

|---|---|---|

| 1/2″ | 3/8″ | FTG-125-101 |

| 1/2″ | 1/2″ | FTG-125-102 |

Type R3: Straight Threaded Copper Fitting

Straight threaded fitting is brazed to the cooling tube extensions, providing an easy and quick method for connecting cooling lines. Recommended to be factory installed to assure good braze seals.

Available for 3/8″ and 1/2″ diameter tubing with internal threads. If required, specify.

| Diameter Tubing |

NPT | Part Number |

|---|---|---|

| 3/8″ | 3/8″ | FTG-131-103 |

| 1/2″ | 3/8″ | FTG-131-102 |

| 1/2″ | 1/2′ | FTG-131-101 |

Installation Accessories

Tubing for Cooling Lines

Cooling Line Tubing can be used to connect the Tempco Cast-In heat/cool bands to the plumbing system of your extruder. Tubing is available in 6’8″ lengths for U.P.S. shipments and up to 20′ lengths for truck shipments. Barlow’s formula below was used to calculate Working Pressure in the table.

Wire Braided Hose

Flexible Teflon® Wire Braided Hose provides an excellent means of connecting Cast-In Heaters to the extruder plumbing system. This style of hose meets the demands of medium to tight bending radius requirements. The stainless steel braid protects the Teflon® hose from any harsh mechanical conditions that may be present.

Additional Options

125 RMS Standard

RMS Surface Finish as defined in ASME B46.1 — RMS is the root mean square of the profile height deviations from the mean line, recorded within the evaluation length. The standard surface finish for the machined surface of Tempco cast-in heaters is 125 RMS. Consult Tempco if a different surface finish is required.

Special Features

Electroless Nickel-Plated — A plating technique (without using an electric current) used to deposit a coating of nickel on a substrate to prevent corrosion, wear and also as a protective coating.

Teflon Coating — Teflon is non-reactive so it is often used in containers and pipework for reactive and corrosive chemicals.

Hard coat anodizing — Anodizing increases resistance to corrosion and wear.

Magnaplate — Strong wear and corrosion resistance non-stick coating that withstands high temperatures.