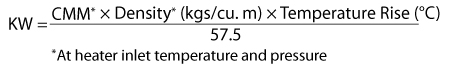

Tempco Calculating Minimum Wattage Requirement

![]()

This table is for quick-estimation purposes and is based on air under standard conditions (70°F inlet air temperature at 14.7 PSIA).

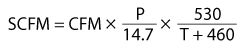

If flow is given in CFM at operating temperature and pressure it can be converted to SCFM (Standard Cubic Feet per Minute) with the following formula (use the equations to the right for compressed air):

P = operating pressure (gauge pressure + 14.7)

T = operating temperature

Note: Remember when calculating wattage to use the maximum anticipated air flow and to compensate for any heat losses.

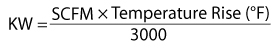

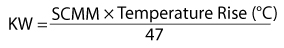

For free air use equations:

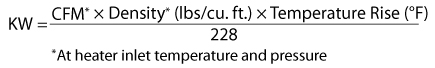

For compressed air use equations:

KWH to Heat Air at Selected Flow Rates

| Amt. of Air CFM |

Temperature Rise (°F) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | |

| Kilowatt Hours to Heat Air | |||||||||||

| 100 | 1.7 | 3.3 | 5 | 6.7 | 8.3 | 10 | 11.7 | 13.3 | 15 | 16.7 | 20 |

| 200 | 3.3 | 6.7 | 10 | 13.3 | 16.7 | 20 | 23.3 | 26.7 | 30 | 33.3 | 40 |

| 300 | 5.0 | 10 | 15 | 20 | 25.0 | 30 | 35.0 | 40.0 | 45 | 50.0 | 60 |

| 400 | 6.7 | 13.3 | 20 | 26.7 | 33.3 | 40 | 46.7 | 53.3 | 60 | 66.7 | 80 |

| 500 | 8.3 | 16.7 | 25 | 33.3 | 41.7 | 50 | 58.3 | 66.7 | 75 | 83.3 | 100 |

| 600 | 10 | 20 | 30 | 40 | 50.0 | 60 | 70.0 | 80.0 | 90 | 100 | 120 |

| 700 | 11.7 | 23.3 | 35 | 46.7 | 58.3 | 70 | 81.7 | 93.3 | 105 | 116.7 | 140 |

| 800 | 13.3 | 26.7 | 40 | 53.3 | 66.7 | 80 | 93.3 | 106.7 | 120 | 133.3 | 160 |

| 900 | 15 | 30 | 45 | 60 | 75.0 | 90 | 105 | 120 | 135 | 150 | 180 |

| 1000 | 16.7 | 33.3 | 50 | 66.7 | 83.3 | 100 | 116.7 | 133.3 | 150 | 166.7 | 200 |

| 1100 | 18.3 | 36.7 | 55 | 73.3 | 91.7 | 110 | 128.3 | 146.7 | 165 | 183.3 | 220 |

| 1200 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 240 |