SwiftSensors Vibration Monitoring

Swift Sensors equipment monitoring solutions include advanced wireless vibration sensors that provide data to optimize and protect equipment and infrastructure in industrial manufacturing and other commercial facilities. Precise monitoring of industrial equipment performance such as motors, pumps, CNC machines, and turbines, enables engineers to maintain compliance with safety and efficiency standards, lower energy costs, prevent equipment malfunctions, and reduce maintenance expenses. Wireless vibration sensors provide continuous, real-time monitoring, alerting engineers to any deviations from the desired ranges, power outages, or equipment failures.

Track performance over time to optimize equipment utilization and identify preventative maintenance opportunities. Receive instant mobile alerts when measurements exceed configured thresholds, enabling immediate corrective actions when equipment performance falters. Swift Sensors wireless vibration monitoring solutions offer reliable, efficient, and scalable options, enhancing operational efficiency and ensuring the highest standards of safety and quality control.

- Real-time Monitoring & Alerts.

- Scalable and Flexible Sensor Network.

- Comprehensive Data Analytics

- User-Friendly Dashboard.

- Battery-Powered and Wireless.

Vibration Monitoring for any Industry

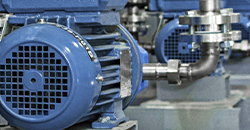

Pumps

By delivering real-time data and alerts, wireless sensors enable effective vibration monitoring of pumps, ensuring timely maintenance to prevent failures and maintain efficiency.

CNC Machines

Wireless sensors help with vibration monitoring of CNC machines by providing real-time data and alerts, allowing for immediate maintenance actions to prevent damage and ensure optimal performance.

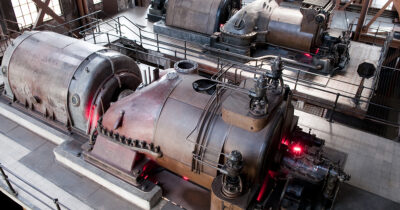

Turbines

Vibration monitoring of industrial turbines is essential for early detection of mechanical faults, preventing catastrophic failures, optimizing performance, and extending equipment lifespan.

Motors

Wireless sensors enhance vibration monitoring of industrial motors by providing continuous data and rapid alerts, allowing for proactive maintenance to prevent malfunctions and ensure reliable performance.