SwiftSensors Vibration Monitoring

Vibration monitoring is vital for maintaining the health and efficiency of machinery and infrastructure in various industries, including manufacturing, facility management, and building maintenance. Swift Sensors wireless vibration sensors provide real-time data on equipment vibrations, enabling early detection of potential issues such as imbalances, misalignments, and wear. By identifying and addressing these problems promptly, you can prevent costly downtime, extend the lifespan of your machinery, and ensure smooth operations. Their easy-to-deploy, scalable vibration monitoring solutions offer robust analytics and instant mobile alerts, helping you optimize preventative maintenance schedules, improve safety, and enhance overall operational efficiency.

Most Popular Applications

Pumps

By delivering real-time data and mobile alerts, wireless sensors enable effective vibration monitoring of pumps, ensuring timely maintenance to prevent failures and maintain efficiency.

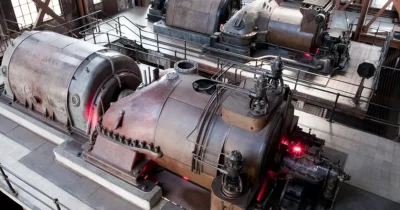

Turbines

Vibration monitoring of industrial turbines is essential for early detection of mechanical faults, preventing catastrophic failures, optimizing performance, and extending equipment lifespan.

CNC Machines

Wireless sensors help with vibration monitoring of CNC machines by providing real-time data and mobile alerts, allowing for immediate maintenance actions to prevent damage and ensure optimal performance.

Motors

Wireless sensors enhance vibration monitoring of industrial motors by providing continuous data and instant mobile alerts, allowing for proactive maintenance to prevent malfunctions and ensure reliable performance.