Individual system solutions for aluminium die casting

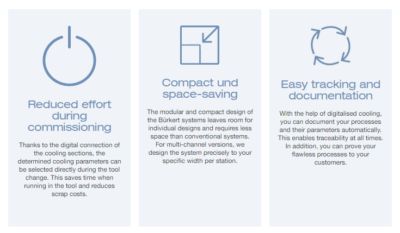

In aluminium die casting, reproducible process conditions are an important basic requirement in order to be able to supply cast parts of a consistently high quality. Foundries must therefore also address the issue of cooling, as efficiently controlled cooling has a decisive influence on part quality. Documenting the actual cooling parameters therefore makes a decisive contribution to process reliability and product quality.

Efficiently designing customised fluid handling for the die casting industry:

Burkert also analyses processes because as fluidics experts, we develop solutions for your aluminium die casting applications – from customised components to individually tailored systems. You will find a selection here – discover more with a non-binding consultation.

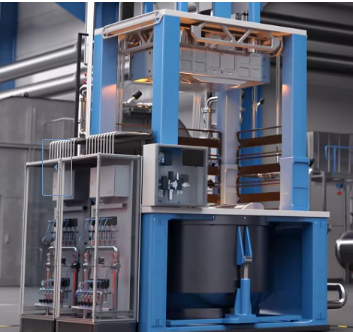

Efficient cooling for low-pressure casting.

Degassing:

Efficient gas control.

Burkerts MFCs efficiently control the process gases in your degassing system.

Bürkert Systemhaus – always open for fluidics technology requirements in the aluminium die casting industry:

The development of reliable fluid handling solutions in the die casting industry is complex and time-consuming. Use the know-how of our fluidics specialists to operate more efficiently. We listen, analyse and develop future-oriented products and customer-specific application solutions until they are ready for series production. You and your projects are always welcome in the Systemhaus – on site, by telephone or virtually.

Manufacturing Ideas:

Experienced consultants, qualified industry specialists, and dedicated engineers work directly with you to develop solutions for your project-specific requirements in aluminum die casting. Thanks to Burkert’s network of five Systemhaus locations in Germany, China, and the US, you can rely on flexible and efficient project management – from the initial idea to implementing the solution in the die-casting machine or degassing unit.

Measurably Safe, Measurably Efficient: