Solenoid Valves with Energy-Saving Kick and Drop Coil

Media such as fluids or gases must be shut off, released, dosed, distributed or mixed. These tasks are among the tasks undertaken by solenoid valves. This means that they are subject to countless requirements in a wide range of different application environments. The challenge for the future lies in a sustainable and energy-saving solenoid valve solution.

![]()

Controlling media with energy-saving solenoid valves:

Valves with electromagnetic coil systems are widespread in order to automatically control gaseous and liquid media. Their energy efficiency, lower noise emissions and associated long maintenance intervals are becoming more and more important today. Coil systems with Kick and Drop electronics assemblies rely on improved valve performance, energy saving and new milestones with regards to their efficiency.

The solenoid valves with the new Kick and Drop technology are 35% smaller than conventional valves, but just as efficient. Moreover, Kick and Drop prevents environmental impact from occurring, as they work silently and do not cause any unpleasant mains humming or whistling.

What lies behind the Kick and Drop electronics assembly?

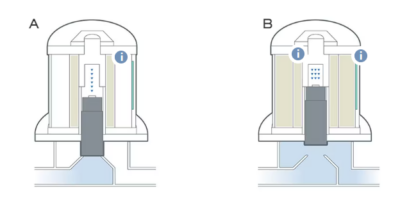

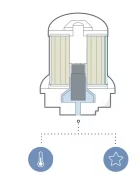

The Kick and Drop coil is a coil with double winding. It consists of an inrush winding and holding winding. In a Kick and Drop electronics assembly, the coil is excited by a high electric impulse. This generates the required inrush power, which the valve needs in order to open. After approx. 500 milliseconds, the Kick and Drop electronics assembly switches to an energy-saving holding power. This then drastically reduces power consumption. The coil is therefore particularly suitable for valves that are open for long periods while in use, such as valves for protecting gas or tap water.

A. The overexcited inrush winding generates a very high starting power over approx. 500 ms

B. The holding winding is connected in series to the inrush winding after 500 ms and reduces the current, and thus the energy demand

Diverse application areas:

The areas of use for the Kick and Drop coil are very diverse, and they are used particularly frequently in the installation and heating sector. The Kick and Drop coil can be used anywhere where the following conditions need to be met:

- Energy should be saved

- Water that contains a particular amount of lime must be controlled

- In buildings where faults must be excluded by electromagnetic fields

- Anywhere where fluids and gases to be controlled must not be heated to over 55 °C

- Anywhere where continuously active solenoid valves, such as gas or tap water safety valves, are operated in buildings

- Anywhere where particularly battery-buffered drainage systems are used, to guarantee a longer, safer operating time

Simple: The printed circuit board integrated into the coil enables the cable plug to be freely selected, saves tedious adjustments and ensures easy start-up.

Simple: The printed circuit board integrated into the coil enables the cable plug to be freely selected, saves tedious adjustments and ensures easy start-up.

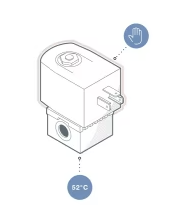

Pleasant: The Kick and Drop coil ensures a quick power reduction. This comes with a reduced surface temperature, from 92° C to only 52 °C. There is no risk of burns.

Pleasant: The Kick and Drop coil ensures a quick power reduction. This comes with a reduced surface temperature, from 92° C to only 52 °C. There is no risk of burns.

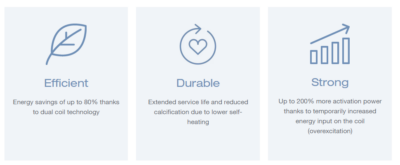

Durable: Thanks to the innovative technology, the self-heating of the coil is reduced by 45 K, which also reduces calcification, and the solenoid valve has an extended service life

Durable: Thanks to the innovative technology, the self-heating of the coil is reduced by 45 K, which also reduces calcification, and the solenoid valve has an extended service life

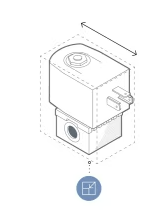

Compact: You will save up to 35% space due to the compact design and the smaller coil.

Compact: You will save up to 35% space due to the compact design and the smaller coil.

Quiet: Thanks to the electronic control in the coil, no disturbing noises occur, such as humming or whistling. This makes application pleasant for humans and animals.

Quiet: Thanks to the electronic control in the coil, no disturbing noises occur, such as humming or whistling. This makes application pleasant for humans and animals.

Diverse: The power supply for the dual coil is universal and frequency-independent. This means that it can be used worldwide, be it with AC, DC, 50 Hz or 60 Hz.

Diverse: The power supply for the dual coil is universal and frequency-independent. This means that it can be used worldwide, be it with AC, DC, 50 Hz or 60 Hz.

Example calculation: