Telemecanique Roller Conveyor Sensors

![]()

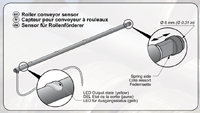

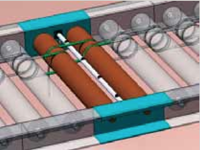

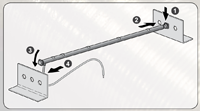

The new XUY roller conveyor sensor from Telemecanique Sensors makes integrating sensors into your roller conveyor system a snap…or, to be more accurate, a click! The innovative, slender design of the sensor fits directly between the rollers of your conveyor and can be installed in mere moments, making time-intensive sensor installations virtually a thing of the past! There are no tools required to install the new XUY roller conveyor sensor and it comes with three mounting solutions (7/16″, Hexagonal, 8 mm, or adhesive adapters).A sensor that lasts!

It is also critical to note that, by default, this revolutionary design of the new XUY roller conveyor actually extends the life of your roller conveyor sensors! Tucked securely between the rollers, the new XUY roller conveyor sensor will not be damaged by collisions with people or machinery passing by the conveyor or by items on the conveyor which are out of their proper position. Downtime due to side- or top-mounted sensor damage is virtually eliminated!Perfect for items such as packets, boxes, or letters!

Whatever the color, shape, or position of object you need to sense, you get 100% detection from the XUY roller conveyor sensor! The infra-red sensing technology of the revolutionary new sensor is not affected by the color of the item you need to sense and sensing direction can be adjusted in 30 degree increments. Full length detection of objects can be accomplished with multiple sensors embedded within the sensor housing and the convex lens of the sensor avoids dust accumulation. The new XUY is the perfect solution for detecting whatever is on your conveyor!

![]() Telemecanique Roller Conveyor Sensor Flyer

Telemecanique Roller Conveyor Sensor Flyer

![]() Telemecanique Roller Conveyor Installation Video

Telemecanique Roller Conveyor Installation Video

![]() Telemecanique Roller Conveyor Sensor Comparison Video

Telemecanique Roller Conveyor Sensor Comparison Video

![]() Telemecanique Roller Conveyor Sensor Overview

Telemecanique Roller Conveyor Sensor Overview

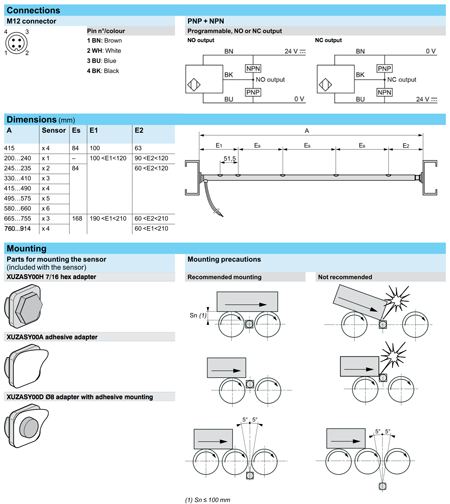

Telemecanique Sensor’s OsiSenseTM XUY photoelectric sensors are really innovative for fast and smart integration in conveyor systems.Fast, modular & best installation time:The sensor is mounted between rollers from the top. No more missing screws to mount your bracket and sensor.

Plug & Play: to see any package, no color effect, and no environment teaching.

Dust protection: special lenses and LED power to avoid dust accumulation

Impact resistant: unique mechanical installation embedded within the conveyor frame to prevent product damage

Full automation integration:

The sensor is compatible with zone controllers from current motorized roller manufacturers or with standard PLC platforms. Different connectors or cable wires are offered.

• Typical areas of application:

• detection of packet, boxes, pallets and

letters of paper, carton or metallic material

• Well suited for use in:

• conveying for manufacturing facilities,

warehouses, and retail distribution centers

Watch a video and see first hand how easy the XUY Roller Conveyor Sensor is to mount and operate –https://www.youtube.com/watch?v=h3h4Y9Efzuk

Benefits

• Fast and simple installation:

• No tools needed

• Easy mounting from the top

• Gain of 50% in installation and adjustment

• 3 mounting solutions (Hexagonal 7/16”, Ø 8 mm, or adhesive supports)

Full detection :

• No package color effecting sensor performance due to reliable infra-red sensing technology

• Easy direction adjustment, every 30°

• Full length detection from multiple sensors embedded within the sensor housing

• Convex lens to avoid dust accumulation

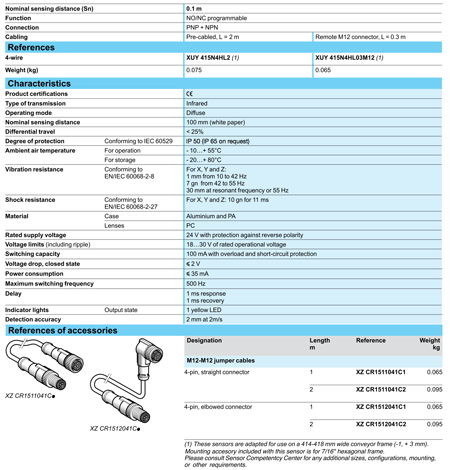

Product Specification

OsiSenseTM XUY

XUY415N4HL2 XUY415N4HL03M12Mechanical Caracteristics:

Dimension (width) Number of sensors

Diameter (case)

Sensor pitch

Connection

Mounting

Material Case

LensDetection performances:

Detection mode

Nominal sensing distance Minimum object size Maximum flow rateElectrical Caracteristics:

Voltage limits

Current consumption Output LED Switching capacity Switching frequencyEnvironmental characteristics:

Operating temperature IP class

Roller conveyor sensor

PNP/NPN, NO/NC by cabling

cable 2m or remote M12 connector415 mm, from 200 to 914 upon request

4 (number of sensors is determined by the overall

conveyor width) 12mm

84 mm

M12 4 pins connector or cable Hexagonal 7/16”, Ø 8mm or adhesive Aluminium and PA

PCDiffuse infrared 100 mm

85 mm

60 m/mn18 to 36 Volts DC (including ripples)

35 mA

yellow

100 mA with overload and short circuit protection 500 Hz-10°C to 50°C

IP50 (IP65 upon request)

XUY Roller Conveyor Sensor

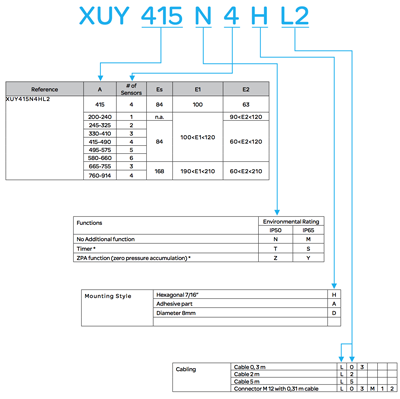

Catalog Number Configuration

For this example, XUY415.. is available for any conveyor width from 414 to 418 mm (-1, +3 mm)

* Future capability. Call local field sales office for more information and availability.

Important Note: Not all configurations may be possible.

Photo-electric sensors

OsiSense XU Application, conveying series

For detecting packages on a roller conveyor

DC supply, solid-state output