Nexthermal Cartridge

Cartridge heaters are versatile and can be configured for optimized performance of a specific application. Many companies can make cartridge heaters. Nexthermal’s goal is to build your cartridge heater. The right cartridge heater, built specifically to your application is one of the most cost effective process improvements you can make. We want to know more about your application, challenges, and goals. Combining your experience with Nexthermal’s thermal transfer expertise will deliver the solution you need.

- Packaging

- Rubber Molding

- Form Fill & Seal

- Platen Heating

- HVAC Compressors

- Die Casting

- Hot Melt Adhesives

- 3D Printers

- Mass Spectrometry

- Food Manufacturing

- Hot Melt Adhesive

- Pellet Stove Igniter

- Torpedo Heaters for Injection Molding

- Heat Staking

- Extrusion

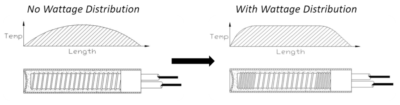

Nexthermal can design the heating element using distributed wattage to correct the temperature curve, resulting in a more uniform heat profile. In the figure below, you can see how the increased wattage in the end zones creates a more uniform temperature curve.

Eagle Sensors & Controls is an authorized Nexthermal distributor. Contact us for sales and application support.