Dalton’s Bore Hole Mystery

Heaters expand, the only question is how much. Fit is the difference between the diameter of the cartridge heater and the bore diameter. The fastest way to move heat from the heater to the tool metal is by conductive heat transfer, which is provided by wall-to-wall contact. Dalton’s Watt-Flex Cartridge Heaters reach set

temperatures faster and recover quicker than traditional heaters.

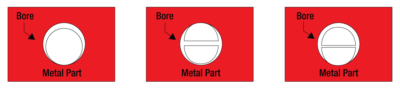

Watt-Flex heaters expand when energized. Contact is made on the top and bottom of the bore and along the length of the heater. Contact produces the maximum conduction heat resulting in the best heat transfer.

The rule for fit is to allow the heater 0.005” to expand. Using a ½” heater (as an example) the heater diameter is 0.495” +/-0.002”. You determine bore diameter by adding 0.005” to the maximum tolerance of 0.497” and obtain a minimum bore of 0.502”. The heater expands, contacting the bore walls, then produces effective conductive heat transfers and long life.

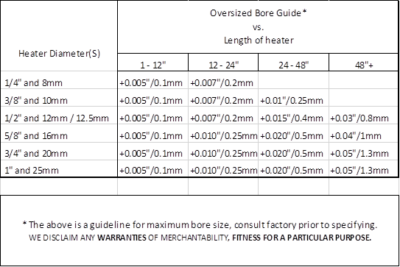

Factors to consider determining bore specifications:

- Long heaters are more tolerant of over-sized bores.

- Short, large-diameter heaters will not expand as longer ones.

- Short, small-diameter, high watt density heaters need tight fit bores.

For more information on Dalton’s Watt-Flex heaters, click here.